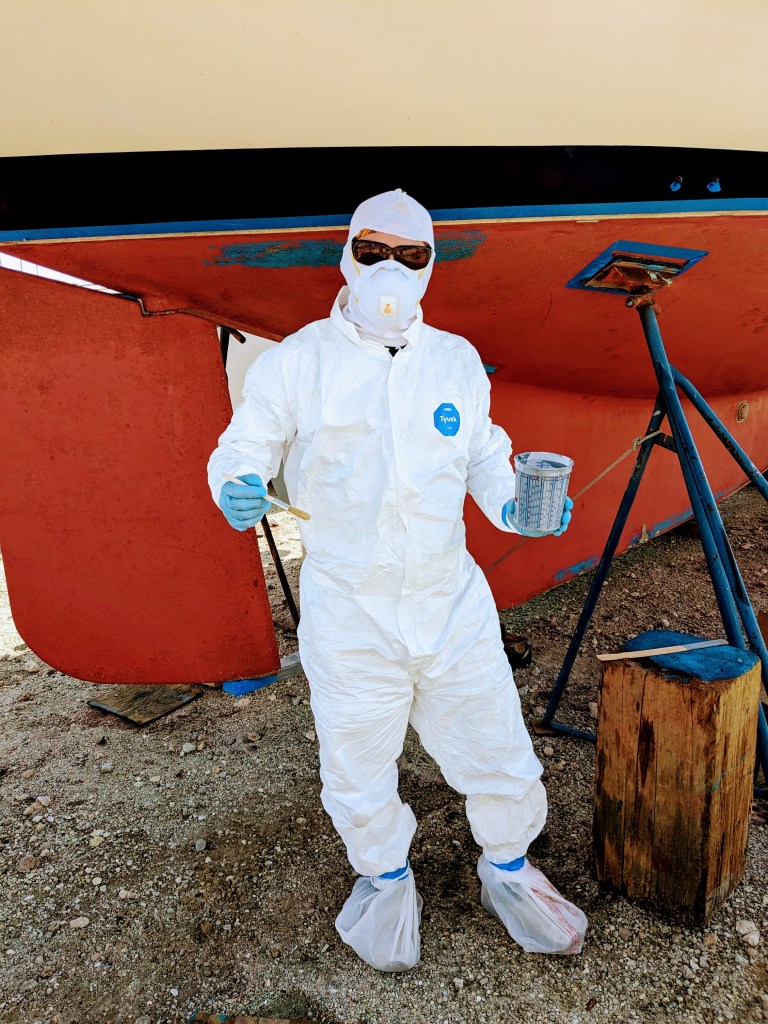

I haven’t been posting many “Keeping it real – life in the boat yard” blog posts recently. Let’s face it, they are kind of a downer. Plus, you don’t really want to see my sweaty, shiny face beaming at you, covered in yard dirt and anti-foul paint, do you? 🥵 But that doesn’t mean we haven’t been hard at work getting SV Happy ready to hit the high seas this winter! Her previous owners took excellent care of her, but she wasn’t outfitted for life on the hook so we had lots to do there, and just to turn her into a comfortable floating home 🏡

Capt. Mike kicked butt in the spring and got a ton of projects finished between when we moved aboard Happy in late March to when we left Stuart, FL in late April:

- Installed 600 watts of solar panels

- New 85 pound Mantus anchor

- New dinghy davits

- Antifoul paint on the hull and prop, with new zincs

- Rebuilt the propane system: lines, regulator, solenoid

- Applied mast boot tape to address a water leak

- Fixed water leak in propane locker

- Waterproofed the Bimini and dodger

- New led light in the galley

- New filters for the drinking water filtration system

- Troubleshooting the wind instruments

- Fixed drawer latches

- New shower head

- Started fixing the portlight leaks… More to follow!

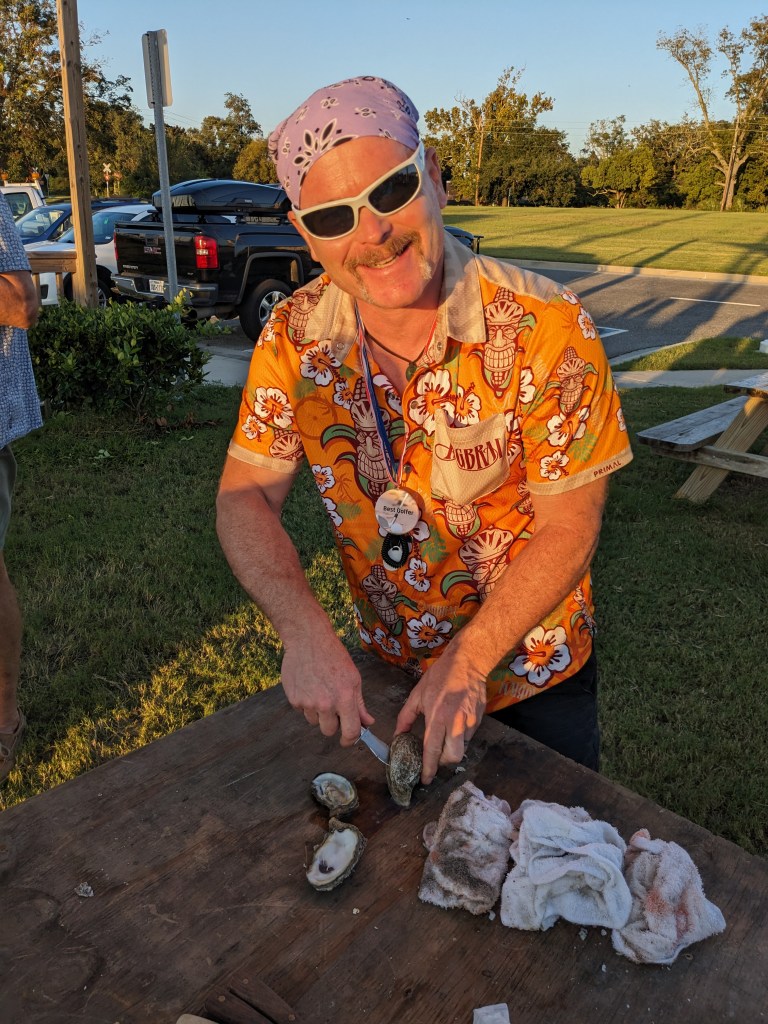

We were feeling pretty good about our progress when we left Happy at Brunswick Landing Marina for a couple months this summer. But after our mountain and cycling summer vacation, we had to go back to work – and in crazy Georgia heat and humidity 🔥 We definitely didn’t feel like we were having as much fun as other residents of the marina.

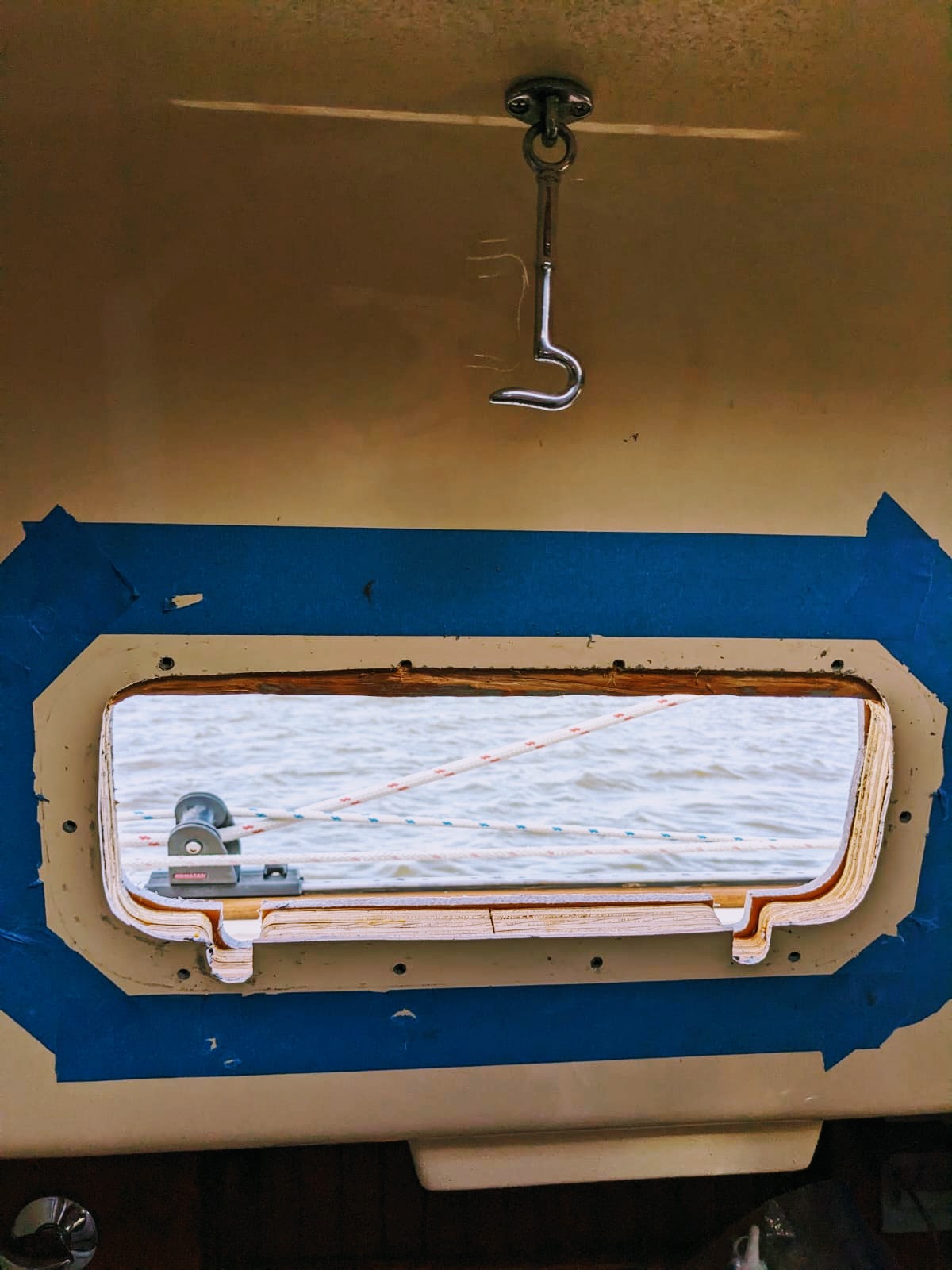

One of our biggest projects was removing all of the portlights (aka boat windows), scraping and cleaning them, and rebedding. In Florida spring thunderstorms, we had water running down the inside of the salon “walls” and collecting inches of water in our drip cups. We decided to repair all the portlights, even the ones without visible leaks, after Capt. Mike installed a light in the galley and water streamed out of the screw holes, implying that some of the leaks were occurring between the hull and the lining. Each portlight took about 8 hours to address – removing with razor blades and pry bars, scraping old caulk and silicon off the stainless, cleaning, rebedding with new caulk, and cleaning the excess that squirted out during the process.

Then the biggest boat project we’ve ever taken on ourselves – installing a high volume water maker / desalinator. A bigger boat means more room for systems and having a virtually unlimited supply of fresh water will be a game changer for our cruising life. But first – we’ve got to get the thing to work! We ordered a Seawater Pro 40 gallons-per-hour system, and it was delivered as a big heavy box of parts and a link to a bunch of You Tube videos. Gulp.

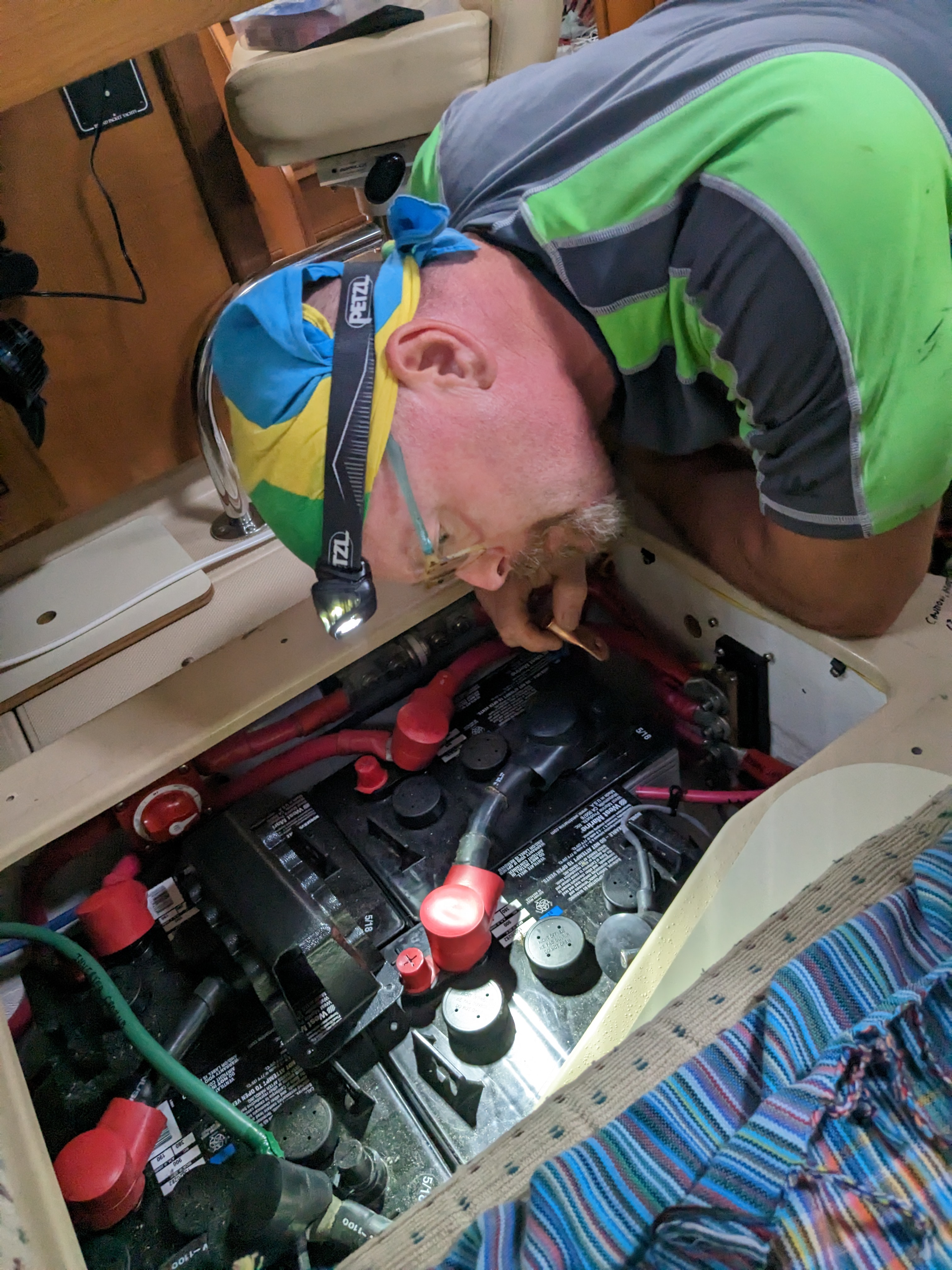

Capt Mike had to figure out where to locate the components of the system (long membranes, water filters, high pressure pump, boost pump, and control panel), and how to connect to the plumbing and electrical systems. At one point, he got frustrated and told me to watch the videos and help him figure out the electrical. I watched each video three times, took pages of notes, and finally announced my findings “They don’t tell you how to connect to the generator and to the boost pump!” Capt. Mike confirmed “That’s exactly my point” 🤦♀️ Luckily, they have excellent customer service and tech support and a couple of phone calls gave us enough info to move forward. It took about a month in total to complete this install, with Capt. Mike contorting his body into every tight hold on the boat. We think he’s got it done! Now to anchor in a place with clean ocean water to test it all out!

Here’s the rest of the project list completed between August and November 2023:

- Rebed 14 portlights

- Install watermaker

- New batteries (house battery bank, starter battery, and bow thruster battery)

- Rebuilt aft head (toilet) pump, replace aft head sink hose

- Added a macerator pump to the aft holding tank

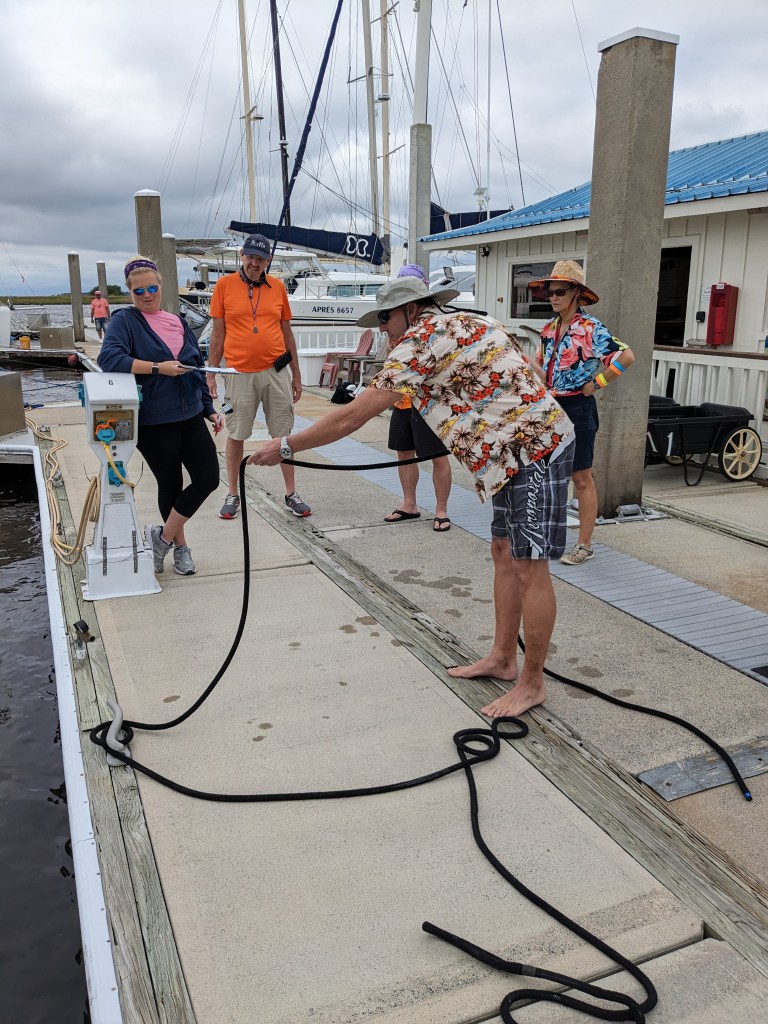

- New running rigging, with new eye splices

- New dock lines, anchor snubber, anchor bridle, and splices

- Install Victron Bluetooth battery monitor

- Brought all three sails to a sail loft for inspection and repairs

- Recaulked both heads and the galley

- Caulked a leak in the forward head fan

- Installed lights in the anchor locker, main cabin closet, and fixed existing light switches

We’re exhausted and our bank accounts are a bit lighter, but we’re ready to get out there and start cruising!