Only four days into our cruising season, and the interior of Sanitas already looks like this.

Yes, even after two months in the boatyard, and another month of boat projects at the dock, we’ve already got our first big repair to make.

I’ve mentioned that we didn’t make power while running the motor on our way from St Petersburg to Key West. What a waste! So we’re trouble shooting the alternator and regulator in Key West where we can get marine grade parts, and even hire experts if needed. It seems to be a different problem than last year – this time the regulator doesn’t even show any error codes, but just has a blank display. So Capt. Mike tore everything apart and got to work.

“Huh. Here’s a wire that’s not attached to anything, and here’s a barrel connector with an empty input. Could that be the issue?” (Acting on the Keep It Simple Stupid principle) So we were off to research the D+ wire and where it should go. A bit later: “Well, here’s a 10 amp fuse that’s blown. Could that be the issue?” So we need to dig out all of the electrical spare parts. Believe it or not …. we don’t have a 10 amp fuse. How is that even possible? So Mike tries a 15 amp fuse instead, just to get us one step forward in trouble shooting.

I had wedged myself into a small clear spot on the port settee, just big enough for my bum, and I’d started working on a blog post when I heard Capt. Mike shout, “I smell something burning! Come help me figure out where it’s coming from. Fast!!” I jumped over all the obstacles between my end of the salon and his, and reached under the nav table to grab a fire extinguisher, and tried to catch up with what was going on. The engine compartment was open, and that’s where we smelled smoke. Mike lifted the cover of the starter battery compartment just on the other side of a bulkhead, and a puff of smoke escaped. Yikes! Fire is one of the most dangerous things possible on a boat. If she capsizes, she’ll right herself, but if she catches on fire, it can all go up in flames pretty quickly.

So we turned off all of the electrical breakers, and bent over the compartment, looking for more smoke and trying to sniff out the source. I restrained myself from using the extinguisher unless absolutely needed because a) it makes a gigantic mess and b) the needle pointed to empty. Oops. Mike pulled the regulator off its mounting and removed the wiring harness, pulling a pin out of the circuit board in the process and we observed a lumpy black scar between the ignition input and field output pins. We each stuck our noses in there to confirm it smelled of melted plastic, and finally determined that was the only burnt component. The new fuse was also blown of course, and that ended any electrical input and risk of fire.

We think the regulator had a short somewhere either inside the electronics or perhaps on the surface near the wiring harness, probably caused by the usual culprit – corrosion. Also, while troubleshooting, we hadn’t disconnected the solar panels. We later learned that electricity generated from those panels can backflow through the alternator and regulator if the path is available. Capt’n Mike has a plan to install an in-line breaker so that we can shut off the solar power flow.

So for now….. we’re safe! And we’ve ordered a new $300 regulator and a new fire extinguisher. (Good thing it only costs $20/night for a mooring ball) And we’ll soon find out whether replacing this component solves all of our problems. Or, if we have a lot more work to do.

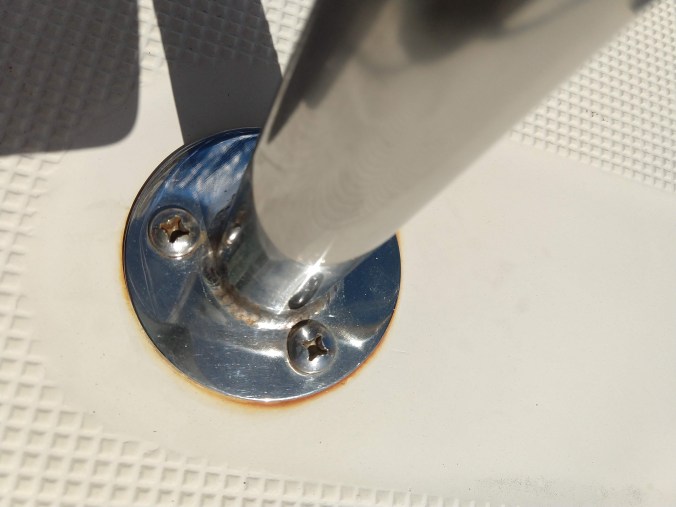

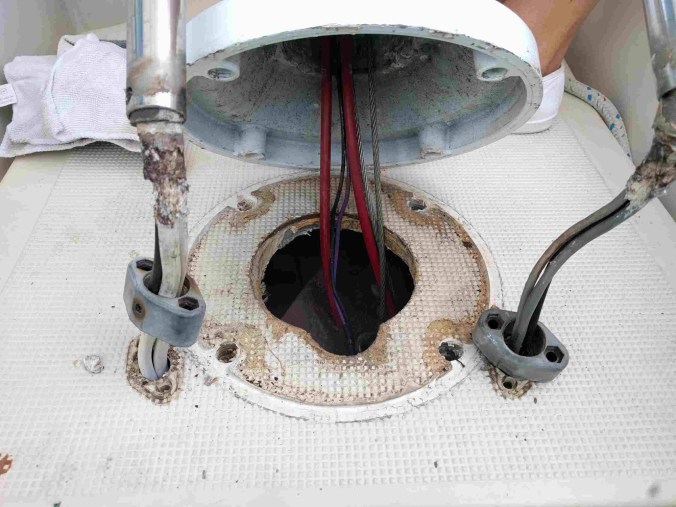

But once we started looking closely at the steering pedestal, we noticed the paint had blistered and developed corrosion underneath. The quick re-bedding project turned into a week-long effort to sand down the blemishes, apply aluminum primer, and to apply four or five coats of white paint. All performed within temperature and humidity levels higher than the manufacturer’s recommendation! we had the cockpit all strung up with trip hazards and “Do not touch -wet paint” signs for over a week, even suspending the steering pedestal in mid air for much of the time to allow it to dry completely.

But once we started looking closely at the steering pedestal, we noticed the paint had blistered and developed corrosion underneath. The quick re-bedding project turned into a week-long effort to sand down the blemishes, apply aluminum primer, and to apply four or five coats of white paint. All performed within temperature and humidity levels higher than the manufacturer’s recommendation! we had the cockpit all strung up with trip hazards and “Do not touch -wet paint” signs for over a week, even suspending the steering pedestal in mid air for much of the time to allow it to dry completely.