After all of our hard work and successful boat projects, Capt. Mike and I were feeling pretty proud of ourselves, and happy to have untied the lines a few days ahead of our 1 Nov goal. Our trip from Brunswick to Stuart, FL started out great with a peaceful anchorage at Cumberland Island and a celebratory glass of tawny port, thanks to our friends Ann and Frank 🥂

We arrived in St Augustine in time on a Friday afternoon to pick up our sails from the Irish Sail Lady’s loft before she closed for the weekend. A sailing couple we’d never met before offered to pick us up with the sails and drive us back to the marina – how nice is that? But then things went downhill… Capt. Mike got sick in St Augustine and spent a few days laid up on the boat. We had to cancel our plans to meet friends over the weekend and it was days before he felt well enough to put the sails back up. We extended our stay on a ball in St Augustine Municipal Marina until he felt better and finally continued south – then things really got dicey!

Anchored in Rockhouse Creek, I guess we got a bit too complacent about our beast of an anchor. We had motored down the ICW from sunrise to sunset, dropped anchor, and I quickly wrangled up a pasta dinner. Just as we started to relax and eat, the anchor alarm blared. Sometimes it’s a false alarm, but not this time – the track of our boat on the little display map was showing a long straight line outside the circle and off to the edge of the screen. Yikes! We were dragging! We rushed back out to the cockpit, started the motor and had to figure out how to re-anchor in the dark without running around on all the shoals and sandbars around us. The anchor had somehow fouled the shaft in its own anchor chain, all wrapped around itself as tidal current fought against wind direction, creating a real mess to put to rights in the dark.

After an uneasy night of sleeping with one ear open for the alarm to go off again, we continued south, finally in a wide enough section of the ICW that we could put out some sail. Winds were about 25 kts from the north and it was a bit rough, even inside the ICW. At one point I heard Capt. Mike say “Huh.” and when I gave him a questioning look, he said “look near the top of the mainsail and tell me what you see.” I said, “I see daylight coming through. That’s not good.” Remember I mentioned picking up our newly repaired sails in St Augustine? Well just a couple of days later and on our first time using them, we’d ripped our main.

We also had a tough time with the bridges on the Daytona Beach section of the ICW. Fixed bridges are supposed to be 65 feet high to accommodate most masts. But with king tides and winds from the north, water was stacking up in this long section with little access to inlets to the sea. We saw bridge boards reading as low as 61 to 62 feet. We aren’t completely comfortable yet with exactly how high our mast is, especially once you factor in the wind instruments and VHF radio antenna. Other sailboats hailed us on the radio and told us they planned to anchor north of the Seabreeze bridges until high tide. We anchored too, to look at the tide tables and to estimate our mast height. With low tide not until 11:30 at night, we decided to go for it anyway, putting out sails to heel us over as much as possible to get a little extra room. We made it, but it made for a nerve wracking day, and we later learned that one of the two anchored boats at Seabreeze damaged their forestay on one of the bridges and had to haul out for repairs.

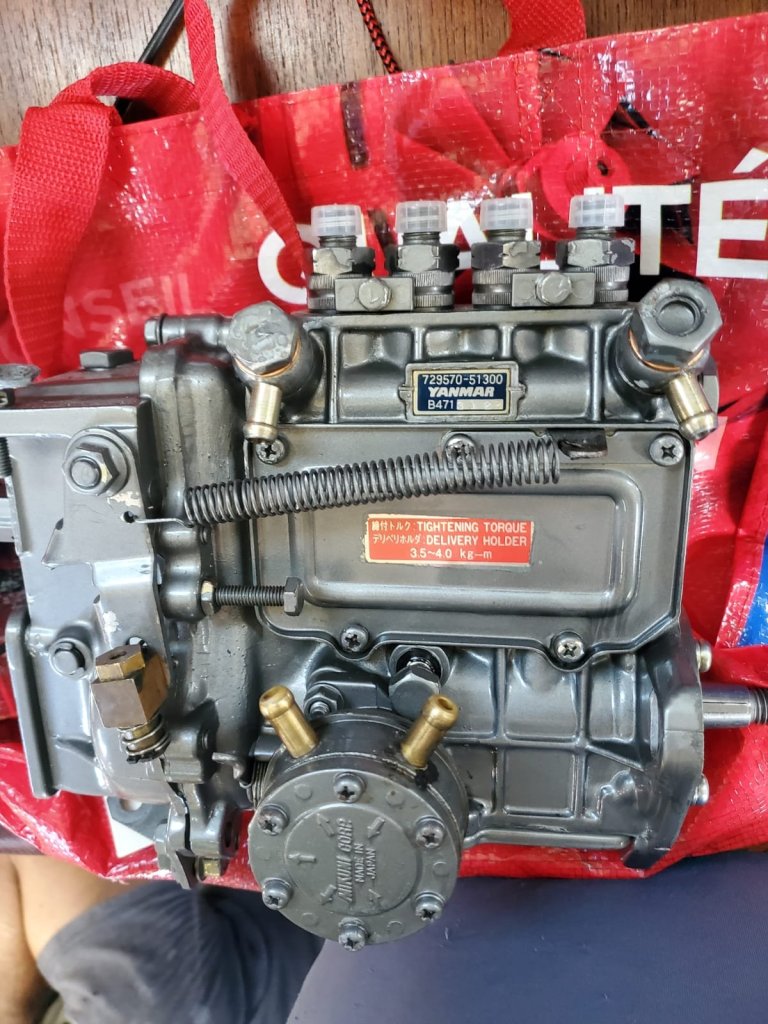

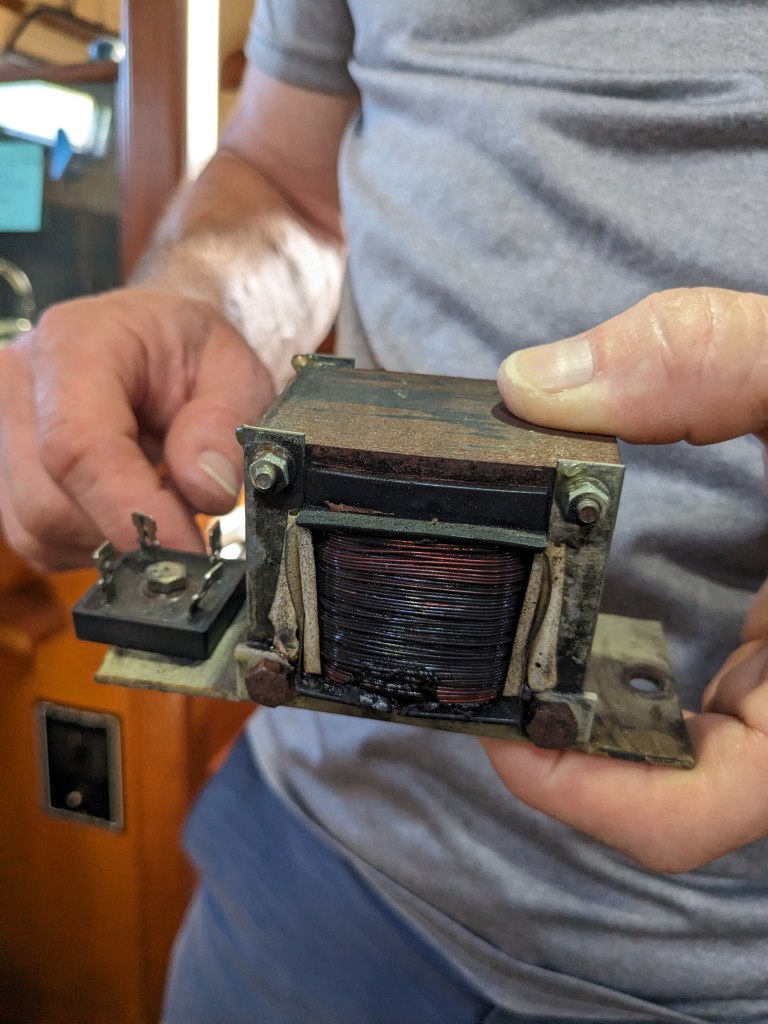

I “celebrated” my birthday on this section of the ICW when we anchored near the Ft Pierce inlet. The Captain surprised me with a margarita after we anchored and I sipped it while reading a book as Capt. Mike got ready to test the new watermaker for the first time. He started the generator, started the water maker, and cheered “It’s working! It’s working!” Then as he came up to the cockpit to celebrate, he changed his tune to “Wait. What’s that horrible burning smell? Shut it all down!” After some investigation, he found a seriously melted part on our nearly new generator. He spent the rest of my birthday evening in the cockpit lazarette grumbling about how he was just going to stay there and cry 😭

We limped the rest of the way to Stuart, FL the next day, attempting to troubleshoot our autopilot. It worked pretty well to turn it on, set a course heading, and to let the autopilot take the helm. But every time we tried to go back to standby and take control away from the autopilot, it wouldn’t give up control easily. Whoever was at the helm would have no control of the wheel for some time between two seconds and fifteen seconds until the clutch would finally release and give us control. That might not sound like a lot of time but if there’s a fast boat coming toward you, or if you are heading outside the dredged channel toward a shoal, it feels like forever. Add that to the list of things we’ll have to repair before leaving Florida for The Bahamas.

So in about a week we went from thinking we were done with all our boat projects and just needed to wait for a weather window to cross to the Bahamas, to having a long list of expensive repairs that all felt like must-dos before leaving the States. Sigh. I know. “That’s boat life.” But somehow it felt pretty depressing. At least we are more in a safe place with lots of marine services and the ability to order parts. I’m sure it’ll all look better soon.